Disinfection of Irrigation Systems, Water, and Surfaces in Plant Cultivation

Disinfectants for Optimal Plant Hygiene

Disinfectants for Optimal Plant Hygiene

Disinfectants and biocides in crop production help mitigate losses caused by plant diseases in many areas. Applications range from surface disinfection to the disinfection of irrigation systems, nutrient solutions, and full-room disinfection in greenhouses, storage halls, and cold rooms.

Reducing post-harvest damage (especially from molds after harvest) is also a critical point. Naturally, only disinfectants with good plant and environmental compatibility can be used for this purpose. Sanosil disinfectants with catalytically enhanced hydrogen peroxide are ideally suited for these tasks.

High-concentration disinfectant for irrigation systems, irrigation water/nutrient solutions, and surfaces

Disinfection super concentrate for irrigation systems, watering solutions/nutrient solutions, and surfaces

Popular applications of Sanosil disinfectants in the cultivation of utility and ornamental plants:

For water systems, only disinfectants and biocides suitable for water disinfection are used, which neither harm the plants nor leave problematic residues. The selection is quite limited, with oxidizing biocides being the most effective. Examples include chlorine, chlorine dioxide, ozone, and hydrogen peroxide.

However, these biocides all have a weakness: they decompose upon contact with organic material and do not provide preventive action. This means that bacterial and fungal regrowth is not actively inhibited and can only be maintained through high re-dosing.

In contrast, hydrogen peroxide with catalytic silver ions—biocides like Sanosil Super 25 and Sanosil S100—not only act more effectively and rapidly against various microorganisms but also have a long-lasting effect. This allows for the use of lower concentrations of active ingredients, which, in turn, protects the plants.

Pythium is a dreaded fungus in plant cultivation, causing severe root rot that can rapidly spread and infect the entire plant population. The disease is caused by the Pythium fungus, which resides in the soil and can be transmitted through infected plant material or water. Root rot caused by Pythium leads to rapid plant death, resulting in significant crop losses and financial damages. The disease can occur in all types of plant operations, including hydroponic systems.

Fusarium is a problem in hydroponic plant cultivation as it is a fungal disease that can be transmitted through contact with infected water, soil, or plant material. Since hydroponic systems typically operate without soil, Fusarium spores can easily spread and infect the plant’s root system. Fusarium causes wilting and yellowing of the leaves and can lead to impaired growth and reduced yields. The disease can spread rapidly and infect the entire hydroponic setup. Moreover, treatment options for Fusarium in hydroponic cultivation are limited as many chemical fungicides are not suitable for hydroponic systems. Therefore, it is crucial to avoid Fusarium infections in hydroponic plant cultivation. This can be achieved by using clean water, sterilized substrates, and healthy plant material. Additionally, adhering to hygiene measures such as regular cleaning and disinfection of equipment and tools is essential to minimize the risk of Fusarium infection.

Crazy Roots / Hairy Roots: Agrobacterium rhizogenes is a single-celled bacterium that disrupts the plant’s hormone balance and causes the roots of infected plants to grow excessively. This particularly damages the cultivation of tomatoes, cucumbers, eggplants, and zucchinis. To slow down and combat the spread of Agrobacterium rhizogenes or the Crazy Roots plant disease, a consistent strategy is necessary. Infected plants must be identified and removed immediately. Regular cleaning of greenhouses, work surfaces, and tools, followed by disinfection, helps with phytosanitation and stops the spread of the bacteria. Regular disinfection of the irrigation system is also crucial in combating Agrobacterium. It’s positive that Agrobacteria are very sensitive to disinfectants like Sanosil Super 25 or SUPER 25 and can thus be easily inactivated.

Pseudomonas and Legionella: These bacteria, which grow particularly well in warm water, are less of a problem for plants but more so for employees. If these bacteria are dispersed as aerosols in the greenhouses, they can cause serious respiratory diseases. However, with consistent water hygiene, the problem can be easily controlled.

In modern agriculture, irrigation systems such as drip irrigation (top feeder, dripping systems), as well as traditional sprinkler systems, are frequently employed. However, the less water flow in such a system and the smaller the pipes and tubes, the more likely biofilms or bacterial and fungal colonies will form.

In the case of thin pipes, these biofilms can lead to blockages of individual sections of the pipeline due to bacterial slime and biofilm plugs. This can result in the loss of individual plant sections if intervention occurs too late.

Depending on the construction of the irrigation system, it can also serve as a vector for the spread of plant diseases. Particularly dreaded fungi like Pythium primarily spread through contaminated irrigation systems.

Continuous addition (low dosage) or discontinuous shock dosing with Sanosil disinfectant are options to keep the entire irrigation system in perfect condition. This prevents biofilms (or bacterial and fungal growth) in tanks and water systems. Thanks to the good compatibility of Sanosil Super 25 disinfectant, even young and delicate plants in hydroponic cultivation can be optimally protected.

To achieve optimal humidity levels in greenhouses, the air must be appropriately humidified. This is typically done by spraying water through misting nozzles (fogging method), either directly into the space or via airflow and fans. As long as water continuously flows through the lines, this is not a problem.

However, if water stagnates in the supply lines to the misting nozzles, germs such as bacteria and fungi proliferate very quickly. In unfavorable cases, these can not only contaminate plants with plant diseases but also endanger the health of workers (Legionella, Pseudomonas). A small amount (20-30 ml of Sanosil Super 25 disinfectant per 1000 liters of spray water) is sufficient to keep humidifiers and misting systems for agriculture free from germs.

When fruits and vegetables are harvested from the field, they are contaminated with various microorganisms such as bacteria, yeasts, fungal spores, and molds. If it is possible to reduce this microbiological contamination before storage begins, the loss due to mold and decay is significantly reduced, and the storage duration is greatly improved.

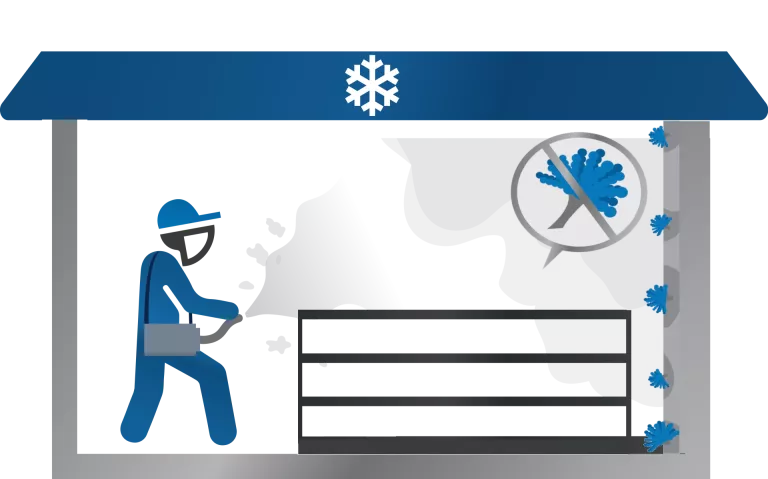

Regular cleaning and disinfection of surfaces of transport containers, storage rooms, machinery, and tools, among others, better protect freshly harvested crops from contamination. This extends their shelf life and storage duration. Various spray, cold, and hot mist devices designed for the treatment of surfaces or spaces with chemicals are suitable for application.

Our core competencies include the manufacturing and application consulting of disinfection products for water systems, surfaces, and air (complete room disinfection).